Email cannot be empty

Password cannot be empty

Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

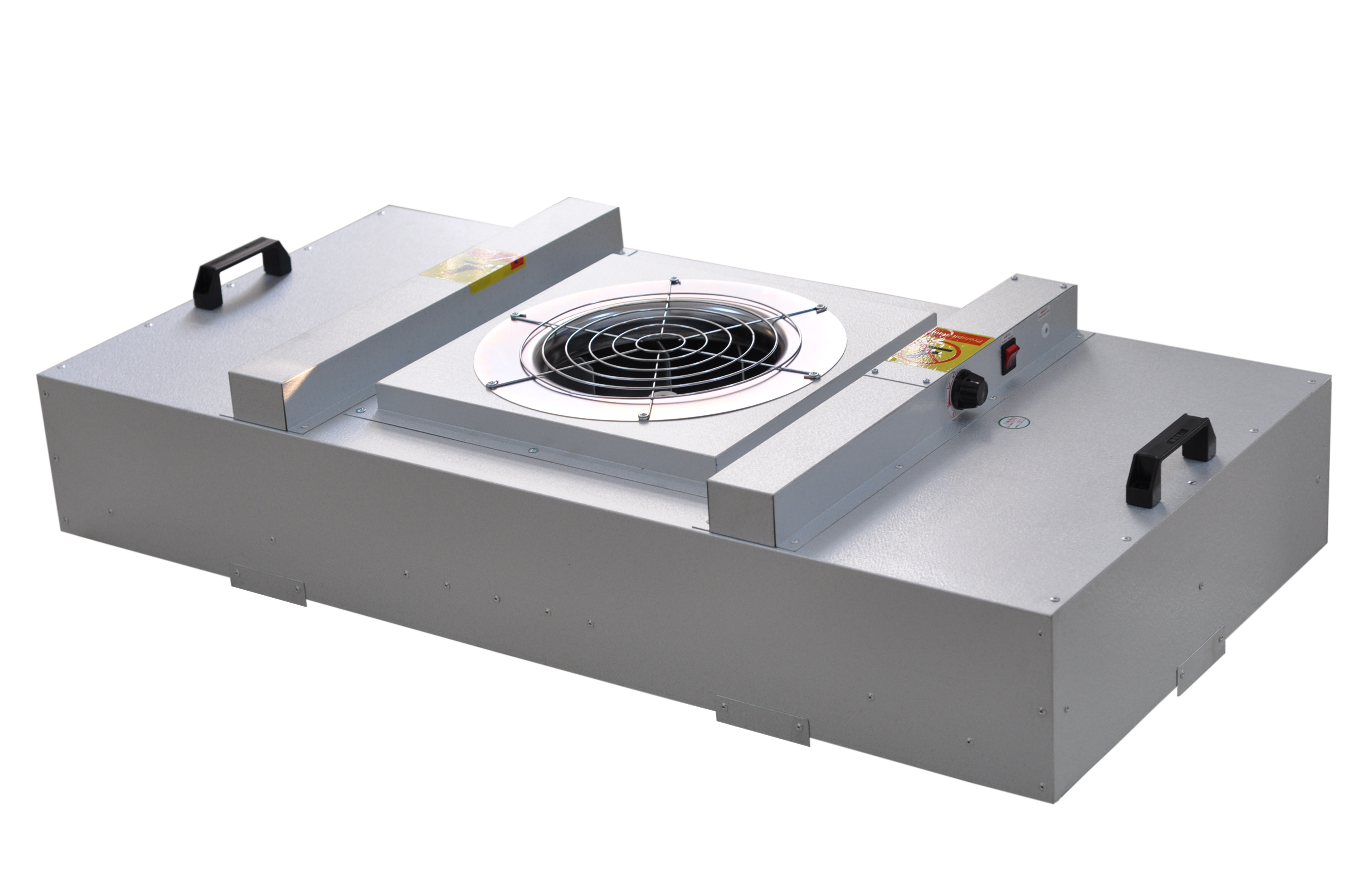

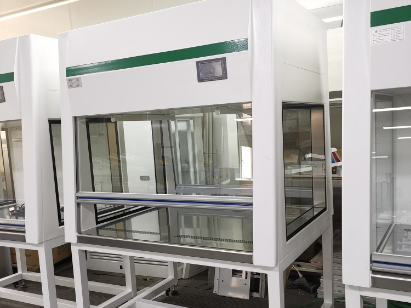

Vertical Laminar Flow Clean Bench

The Deshengxin Vertical Laminar Flow Clean Bench is an advanced piece of equipment specifically designed for fields such as scientific research, healthcare, biotechnology, and microelectronics. Featuring high-quality stainless steel construction combined with electrostatic spray paint or steel plate baking paint surface treatment, this bench ensures robust durability and corrosion resistance while significantly enhancing cleaning convenience and operational efficiency. Its unique vertical laminar airflow design effectively removes particles and contaminants from the air, providing users with a highly clean and controlled work environment. With its outstanding performance, stable operation, and industry-standard-compliant design, the Deshengxin Vertical Laminar Flow Clean Bench is the ideal choice for numerous industries seeking a high-quality work environment.

DSX Vertical Flow Clean Bench

Product Overview

Introducing the DSX Vertical Flow Clean Bench, an advanced air purification device tailored for research, experimentation, and production environments demanding a pristine working atmosphere. Featuring a unique vertical laminar flow design, this bench guarantees air quality compliance with ISO 14644-1 standards, accommodating diverse cleanliness requirements across industries.

Key Features

Design Features:

- Vertical Laminar Flow Technology: Ensures a stable and uniform airflow, effectively mitigating dust and microorganism spread.

- High-Efficiency Filtration System: Equipped with state-of-the-art HEPA or ULPA filters to meticulously capture airborne particles and microorganisms.

- Modular Design: Facilitates easy disassembly and assembly for seamless cleaning and maintenance.

- User-Friendly Operation Interface: An intuitive control panel and straightforward operation buttons enable effortless adjustment of parameters like airflow speed and lighting.

Product Highlights:

- Vibration-Free Work Table: Separated from the clean bench frame for uninterrupted operation.

- Durable Work Table: Constructed from stainless steel for wear resistance and ease of cleaning.

- Mobility: Universal wheels at the base for convenient movement and installation.

- High-Quality Fan System: Characteristics include longevity, low noise, maintenance-free operation, minimal vibration, and stability. Capable of rotating over 50,000 hours.

- Continuous Variable Transmission: Maintains optimal airflow speed.

Technical Specifications

- Working Area Dimensions: 1200mm x 800mm (customizable)

- Airflow Speed Control Range: 0.3-0.5m/s (customizable)

- Cleanliness Level: Class 100 (customizable)

- Power Requirements: AC 220V, 50Hz (varies by model)

Application Areas

The DSX Vertical Flow Clean Bench is a staple in semiconductor manufacturing, electronics, biopharmaceuticals, food processing, research laboratories, and more, providing a dependable clean environment for high-precision manufacturing and research endeavors.

Advantages Analysis

- High-Efficiency Cleanliness: Vertical laminar flow design guarantees workspace air purity.

- Stable and Reliable: Advanced control systems and robust mechanical structures ensure long-term operational stability and reliability.

- User-Friendly Operation: Intuitive interface and straightforward procedures enable swift operator onboarding.

- Energy-Efficient and Eco-Friendly: High-efficiency energy-saving technology minimizes operational costs while adhering to environmental standards.

Operation and Maintenance

- Operation: Customizable LCD control panel for streamlined operation.

- Maintenance: Regular filter replacements and cleaning of the workspace and casing ensure optimal performance and extended equipment lifespan.

Additional Benefits

- Certified Quality: CE-certified, widely applied in laboratories and beyond.

- Flexible Configurations: Options for horizontal and vertical laminar flow, single, double, or triple operator models.

- Customizable Sizes: Standard and bespoke sizes to suit individual requirements.

- Cost-Effective: Efficient motor and long-lasting HEPA filter reduce operational expenses.

- Robust and Elegant: High-quality casing material ensures durability and an appealing aesthetic.

Choose the DSX Vertical Flow Clean Bench for unparalleled cleanliness, stability, reliability, and ease of operation. It's a premium-quality, stylish, and competitively priced solution tailored to meet all your research and production cleanliness needs!

All products can be customized as actual requirement

|

|

|

| Laser cutting | CNC bending Center | CNC Punch Press Punching |

|

|

|

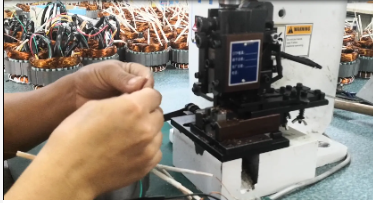

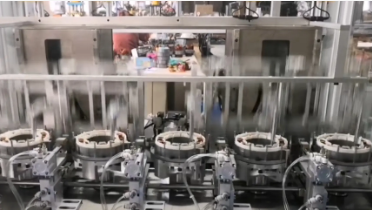

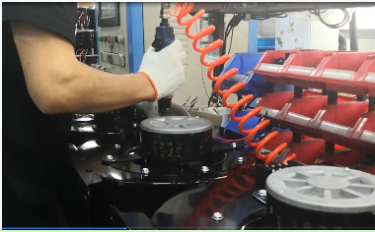

| CNC bending | DSX Motor production | Motor production |

|

|

|

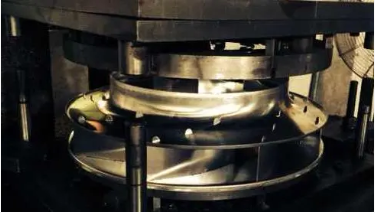

| Motor production | Produce impeller | Balancing the impeller |

|

|

|

| Motor test | Blower production | Blower testing |

|

|

|

| Chemical filters Production | Chemical filters Production | Chemical filters Production |

|

|

|

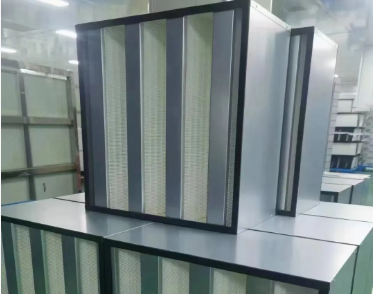

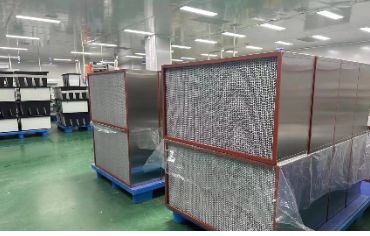

| HEPA filter workshop | Special filter Production | W-type filter production |

|

|

|

| High temperature filter | Rivet workshop | Laser welding |

|

|

|

| Welding workshop | Welding workshop | Cutting of profiles |

|

|

|

| FFU assembly | FFU assembly | FFU assembly |

|

|

|

| Air shower room assembly | Clean bench production workshop | Clean bench production workshop |

|

|

|

| Pass boxes production workshop | HEPA BOXES production workshop | HEPA Boxes test |

|

|

|

| EFU production | Warehouse | Shipment |

FAQ on Vertical Flow Clean Bench

Q1: What is a Vertical Flow Clean Bench?

A: A Vertical Flow Clean Bench, also known as a Clean Bench, is a piece of equipment widely used in various fields such as laboratories, biotechnology, microelectronics, optoelectronics, and manufacturing. It features a vertical unidirectional airflow to maintain a high level of cleanliness within a localized area.

Q2: What are the main advantages of a Vertical Flow Clean Bench?

A: Vertical Flow Clean Benches offer several advantages, including high cleanliness, the ability to connect into assembly lines, low noise levels, and mobility. They are designed to provide a controlled environment for sensitive operations.

Q3: In what industries is a Vertical Flow Clean Bench commonly used?

A: Vertical Flow Clean Benches are commonly used in industries requiring a high degree of cleanliness and contamination control, such as laboratories, biopharmaceutical production, microelectronics manufacturing, and areas of hard disk drive production.

Q4: How does the airflow in a Vertical Flow Clean Bench work?

A: The airflow in a Vertical Flow Clean Bench is designed to flow vertically from the top down, ensuring that contaminants are continuously removed from the work area. This vertical airflow pattern is particularly suitable for applications where human health and product purity are critical.

Q5: What materials are used in the construction of a Vertical Flow Clean Bench?

A: Vertical Flow Clean Benches are typically constructed with stainless steel worktables for durability and resistance to corrosion. Surfaces are often treated with electrostatic spray paint or steel plate baking paint to enhance ease of cleaning and maintain a high level of cleanliness. These materials are chosen for their robustness, ease of maintenance, and ability to support a contamination-free environment.

By incorporating high-quality materials such as stainless steel and steel plate baking paint, Deshengxin ensures that its Vertical Flow Clean Benches not only meet but exceed industry standards for cleanliness and durability. These features make Deshengxin's Vertical Flow Clean Benches a reliable and efficient choice for various industries requiring a controlled and contamination-free workspace.

Innovating Cleanliness: Deshengxin Vertical Flow Clean Bench

In today's advanced technological era, maintaining a clean and contamination-free environment is crucial for various industries, including biotechnology, microelectronics, and pharmaceuticals. Deshengxin, a leading manufacturer of cleanroom equipment, understands this need and offers a range of innovative solutions, with the Vertical Flow Clean Bench being one of its standout products.

The Deshengxin Vertical Flow Clean Bench combines state-of-the-art technology with robust construction to provide a controlled environment with high cleanliness levels. Designed with a vertical unidirectional airflow, this bench ensures that contaminants are continuously removed from the work area, creating an ideal workspace for sensitive operations.

One of the key advantages of the Deshengxin Vertical Flow Clean Bench is its versatility. It can be connected into assembly lines, making it suitable for various manufacturing processes. Additionally, its low noise levels and mobility features make it an excellent choice for a wide range of applications.

Deshengxin uses high-quality materials in the construction of its Vertical Flow Clean Bench. The stainless steel worktable and surface treatment with electrostatic spray paint ensure durability, ease of cleaning, and maintenance of cleanliness. These features make the bench suitable for long-term use in demanding environments.

Before leaving the factory, each Deshengxin Vertical Flow Clean Bench undergoes rigorous testing according to American Federal Standard 209E, ensuring high reliability and performance. This attention to detail and commitment to quality make Deshengxin a trusted name in the cleanroom equipment industry.

In conclusion, the Deshengxin Vertical Flow Clean Bench is a versatile and reliable solution for maintaining a clean and contamination-free environment. Its innovative design, robust construction, and high cleanliness levels make it an excellent choice for various industries. With Deshengxin, you can trust that your critical operations will be performed in a controlled and clean environment, ensuring the highest quality results.